Embracing Sustainability in Logistics

Given the increasing importance of strict environmental regulations, reflected in requirements such as emissions reporting, the Paris Agreement is a crucial legal treaty in the field of climate change. This agreement, which was adopted by 196 parties at COP21 in Paris, France, in December 2015, has incentivised companies to pursue more sustainable business practises. In response to this global initiative, companies are actively looking for innovative ways to reduce their environmental footprint. This shift towards sustainability is not only advisable, but essential for the preservation of our planet, as outlined in our Life Cycle Assessment (LCA) study.

Since KraftPal pallets made of corrugated cardboard are up to 80% lighter than conventional EUR1 wooden pallets, the need for environmentally friendly solutions for the use of pallets is greater than ever. For companies that use more than 100,000 EUR1 pallets per year, reducing the carbon footprint up to 80% is important (for GMA 48x40 pallets the reduction percentage is slightly lower and it depends on the customer's needs), but equally important are the potential savings.

Reuters was writing that some companies are setting their own price on the carbon offset: "A growing list of global companies are setting a price or charging themselves for each metric ton of their carbon emissions, looking to shape their investments and business for future pollution taxes or other new climate rules. Their prices are all over the place, from less than 0,91 EUR ($1) per metric ton of carbon emissions to 1463.06 EUR ($1,600), the most of any company worldwide, set by California drugmaker Amgen (AMGN.O)."

In 1990, Finland was the world’s first country to introduce a carbon tax. Since then, 20 European countries have implemented carbon taxes, ranging from less than 1 EUR per metric ton of carbon emissions in Ukraine to more than 100 EUR in Sweden, Liechtenstein, and Switzerland. In the USA, only 13 states currently have U.S. State Carbon Pricing Policies, and the prices of the tax are different from those in the EU.

The location of your business can have a significant impact on how much you save in carbon taxes, especially if you switch from traditional EUR1 wooden pallets to EUR1 KraftPal pallets, which are 80% lighter. Let's take the example of a company in Sweden that needs 100,000 EUR1 pallets per year to transport products over a distance of 1230 kilometres. Opting for conventional EUR1 wooden pallets would result in 230 tonnes of CO2 emissions. Given the Swedish carbon tax rate of 115 EUR (from 2023), this results in a tax burden of 26,450 EUR. However, if 100,000 EUR1 KraftPal pallets were used, the tax would only amount to 4,600 EUR, as KraftPal reduces CO2 emissions per EUR1 pallet by 80%.

The savings are even greater for air freight. For 100,000 air freight pallets, KraftPal pallets lead to emissions of 1,900 tonnes, while wooden pallets cause 10,700 tonnes. Expressed in monetary terms, this corresponds to a carbon tax of 218,500 EUR for KraftPal compared to 1,230,500 EUR for air freight wooden pallets. In air freight scenarios, this difference equates to savings in the millions. For more details and calculations on your exact savings, please email sales@kraftpal.com. However, the figures for reducing your carbon footprint can be found further down in this article.

The Need for Eco-Friendly Solutions in Pallet Use

The global pallet market is experiencing a significant upturn. According to the Pallet Market 2023-2028 study by iMarc's Pallet Market the market reached an impressive 7,724 million units in 2022, which corresponds to a compound annual growth rate (CAGR) of 3.4% from 2017 to 2022. The forecast for the period 2023 to 2028 envisages a further increase with a CAGR of 4.5% and anticipates a volume of 9,947 million units by 2028.

Wooden pallets dominated the market in 2022 with a 90.3% share of the total volume. It is noteworthy that one third of these wooden pallets are intended for one-way transport. The growth of global trade and the need for efficient goods transport are driving companies like KraftPal.

Despite the widespread use of traditional wooden pallets, they pose a significant environmental problem, such as deforestation and increased carbon emissions. In this context, KraftPal's corrugated pallets are proving to be a more environmentally friendly option that addresses these concerns.

Protecting the Forests - The lungs of the Planet

Minimizing deforestation is critical to maintaining the health of our planet's forests, which act as vital lungs by absorbing carbon dioxide and releasing essential oxygen. Forests play a key role in biodiversity, providing habitat for countless species and maintaining ecological balance. They also play a central role in regulating climate patterns and rainfall, with their destruction potentially leading to more extreme weather conditions worldwide.

Forests serve as natural carbon sinks and help to mitigate the effects of climate change by sequestering large amounts of carbon. The protection of forests is also linked to the well-being of indigenous communities who depend on them for their livelihoods and cultural heritage.

KraftPal's pallets are made from FSC-certified corrugated cardboard that we source from DS Smith or Stora Enso, which significantly reduces wood consumption compared to conventional wooden pallets. The difference in resource efficiency is striking only 6 wooden pallets can be produced from an average tree, which yields around 300kg of wood, whereas the same tree can produce 24 cardboard pallets. This means that a single tree can provide about 4.1 times more cardboard pallets than wooden pallets, significantly reducing the impact of deforestation.

While wooden pallets are made from durable, high-quality wood, corrugated cardboard comes from faster-growing tree species. In addition, the pulp used in corrugated cardboard can be recycled 6 to 8 times before the fibers become too weak, increasing its sustainability.

Production Phase: A Clear Advantage for Cardboard

KP corrugated cardboard pallets have a remarkably low CO2 footprint during production compared to their wooden counterparts. Research shows that only 2.21kg of CO2e is emitted during the production of a single cardboard pallet, significantly less than the 5.00kg of CO2e emitted during the production of a wooden pallet. This significant reduction in carbon emissions of 55.7% is due to the efficient use of raw materials and the application of more environmentally friendly production techniques. Furthermore, the production of wooden pallets not only requires a higher consumption of raw materials, but also the use of slightly less than 80 nails per pallet. Nails are known to be a very energy-intensive and high-consumption product.

Sustainable Practices with FSC – certified cardboard providers

As previously mentioned, KraftPal's collaboration with DS Smith in Austria and Stora Enso in Finland, both leading suppliers known for their commitment to sustainable practices, underscores the company's commitment to environmental protection.

These partners, DS Smith, and Stora Enso, guarantee sustainable management of their forests and ensure that all forestry materials used in their production processes are responsibly sourced. These partnerships are a testament to KP commitment to protecting the environment.

In addition, KP has a strict paper policy and only purchases FSC or PEFC certified cardboard, reflecting our strong environmental ethos. The company is also actively pursuing FSC and PEFC certification, underlining its ongoing commitment to sustainable business practices.

Product Use: Transportation Efficiency

The principle is simple: lighter pallets mean less energy consumption and therefore lower emissions. KP corrugated cardboard pallets epitomize this concept and offer a significant reduction in CO2e emissions, as confirmed by the LCA study. This direct relationship between weight and energy efficiency is key to understanding the environmental benefits of these pallets.

KP pallets are characterized by their significantly lower weight during the transport phase, which represents a remarkable advantage for the environment. The Life Cycle Assessment (LCA) study shows that the use of these corrugated pallets can lead to a remarkable reduction in CO2e emissions of 81.8% to 83.3%, depending on the mode of transport. The key to this significant reduction lies in the lower weight of the pallets, which leads to lower fuel consumption and consequently lower CO2 emissions. This makes KraftPal pallets an environmentally friendly choice for logistics and transport.

Impact on Air and Sea Freight

A subtle but decisive factor lurks in the air and sea freight sector, - the weight of the pallets. A detail that has an immense impact on fuel efficiency. But here's a revelation that may amaze and inspire you: Our company has developed air freight pallets that change the carbon footprint as they take to the skies. With our Airfreight KP pallets, flying becomes a ballet of efficiency. These pallets are amazingly light and allow for a denser load per aircraft. The impact on the environment? Significantly. Our KP pallets have an 82.2% lower CO2e emission ratecompared to conventional wooden pallets. Expressed in figures: wooden pallets emit a whopping 107 kg of CO2e, while our KP pallets only contribute a "tiny" 19 kg. That's not just an improvement, it's a big leap in one of the most environmentally intensive transport sectors. The ethos of our company? We want to help other companies drastically reduce their environmental footprint through our innovative products. Embrace this change with us and redefine air freight for a more sustainable Europe.

There is an exciting wave of change in the dynamic world of sea freight. A.P. Moller - Maersk, a titan in logistics, has set a precedent by procuring green methanol for the inaugural voyage of the world's first methanol-fueled container ship. This breakthrough in green fuel is a defining moment not only for Maersk, but for the entire industry in its endeavor to reduce greenhouse gas emissions.

However, there is an urgent reality that we must face. Until other logistics giants can free their fleets from dependence on diesel fuel, the impact on the environment will remain significant. Currently, every wooden pallet used in sea freight generates 1.1kg of CO2e. But there is a glimmer of hope: our KP corrugated cardboard pallets. By switching to these ingeniously designed pallets, we can reduce CO2 emissions by an astonishing 83.3%. This dramatic reduction to just 0.2 kg CO2e per pallet is mainly due to their significantly lower weight.

This progress is not just a small step, but a big leap towards a more sustainable future for sea freight. While we wait for a broader industry shift to greener fuel alternatives, our KP pallets offer an immediate, impactful solution. Together, we can lead the way to a cleaner, more responsible maritime world.

End of Life: Superior Recyclability

KraftPal's corrugated pallets offer a more sustainable end-of-life solution, with an impressive, estimated recycling rate of over 99%. Not only are these pallets easy to recycle, but they often contribute to the manufacture of new cardboard products, including further pallets.

In comparison, the recycling of wooden pallets is more complicated and less commonly practiced, resulting in a significant number of pallets ending up in landfill. The labor-intensive recycling requirements for wooden pallets, such as removing the nails, result in a much lower recycling rate.

Paper and cardboard, as well as materials such as aluminum, glass, and steel, are among the most recyclable materials. Crucially, KP pallets can be recycled through existing recycling infrastructures, utilizing the systems already in place for efficient and environmentally friendly disposal.

Landfilling

Landfilling has been identified as the fourth-largest source sector of emissions, accounting for 3% of total GHG emissions among the EU-28 in 2017. The reduction of 13,6% in emissions from solid waste disposal for the EU-28 members follows the reduction in the amount of landfilling and increase in recovery of landfill gas (EUROSTAT, 2020). The EU legislation through various Directives, such as Landfill Directive 1999/31/EC, steers the national legislations to take measures to reduce the production of methane gas from landfills by reducing the landfill of biodegradable waste (European Council, 1999).

Net GHG Reductions

Recycling corrugated cardboard results in net greenhouse gas reductions. When compared to the end-of-life scenario for wooden pallets, which often involves landfilling or incineration, KraftPal's pallets offer a more sustainable solution, leading to significant reductions in overall carbon emissions.

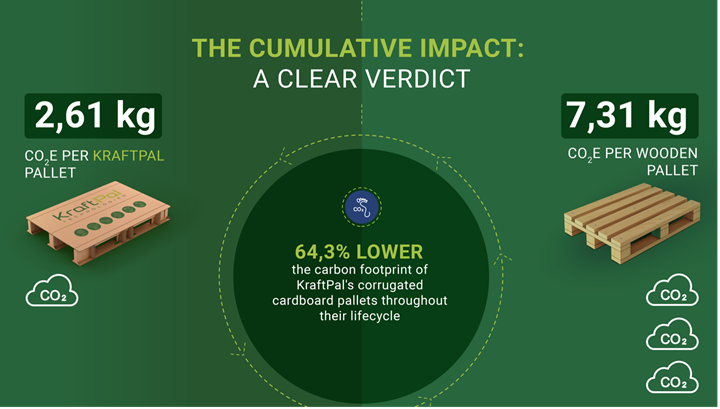

The Cumulative Impact: A Clear Verdict

Cumulatively, the carbon footprint of KraftPal's corrugated cardboard pallets throughout their lifecycle is 64,3% lower than that of wooden pallets (2,61 kg CO2e vs. 7,31 kg CO2e). This significant reduction underscores the environmental benefits of switching to our solution.

Meeting Sustainability Goals

For businesses aiming to reduce their environmental impact, switching to KraftPal's corrugated cardboard pallets can be a strategic move. It aligns with global efforts to combat climate change and supports corporate sustainability goals.

The Future arrives on a KraftPal pallets

As we reach the culmination of our exploration into the field of sustainable logistics, it becomes clear that KraftPal's corrugated pallets are not just an alternative, but a much needed change in environmental responsibility. Our pallets are more than just a product; they are a testament to a sustainable future, representing a reduced carbon footprint, environmentally friendly production, efficient transport and unparalleled recyclability. They are the key to realising your company's potential in terms of sustainability.

Choosing KraftPal is not only a business decision, but also a bold step towards a greener future. KraftPal's pallets reflect the global call for environmental responsibility and fit perfectly with the stringent measures outlined in the ITF Climate Action Directory. Whether it's complying with the carbon tax on road vehicles, eliminating the fossil fuel tax exemption for maritime transport, aligning with road and toll charges or aligning with the aviation fuel tax, KraftPal's lightweight pallets serve as a beacon for efficiency and sustainability. They drastically reduce fuel consumption and emissions and enable greater freight capacity, resulting in fewer journeys and a significantly lower environmental impact.

At a time when every action counts for the health of our planet, adapting to the sustainability guidelines of the OECD and the International Transport Forum is not only smart, but necessary. KraftPal offers a solution that fulfils these global standards. So you can ensure that your organisation is not only part of the change, but also playing a leading role.

As we close this chapter, the call to action is clear. Move into the future with KraftPal and choose a solution that offers more than just logistical efficiency; choose a path that leads to a sustainable, environmentally conscious future. Contact the dedicated team at sales@kraftpal.com for more information.