Since World War II, enormous effort and resources have been expended in the paper and corrugated industries to develop corrugated pallets that had the potential to replace wooden pallets in the supply chain. All attempts failed to find a viable solution for the mainstream market. KraftPal's recent introduction of corrugated pallets to the market would bring tremendous benefits in terms of economic cost savings, environmentally friendly CO2 reduction, and full recyclability, which is an undeniable requirement for the circular economy. All over the world, suppliers and shippers are looking for sustainable packaging, ease of logistics handling and efficiency in downstream material transportation. The reinvention of corrugated pallets is a new paradigm that will change the material handling and distribution market.

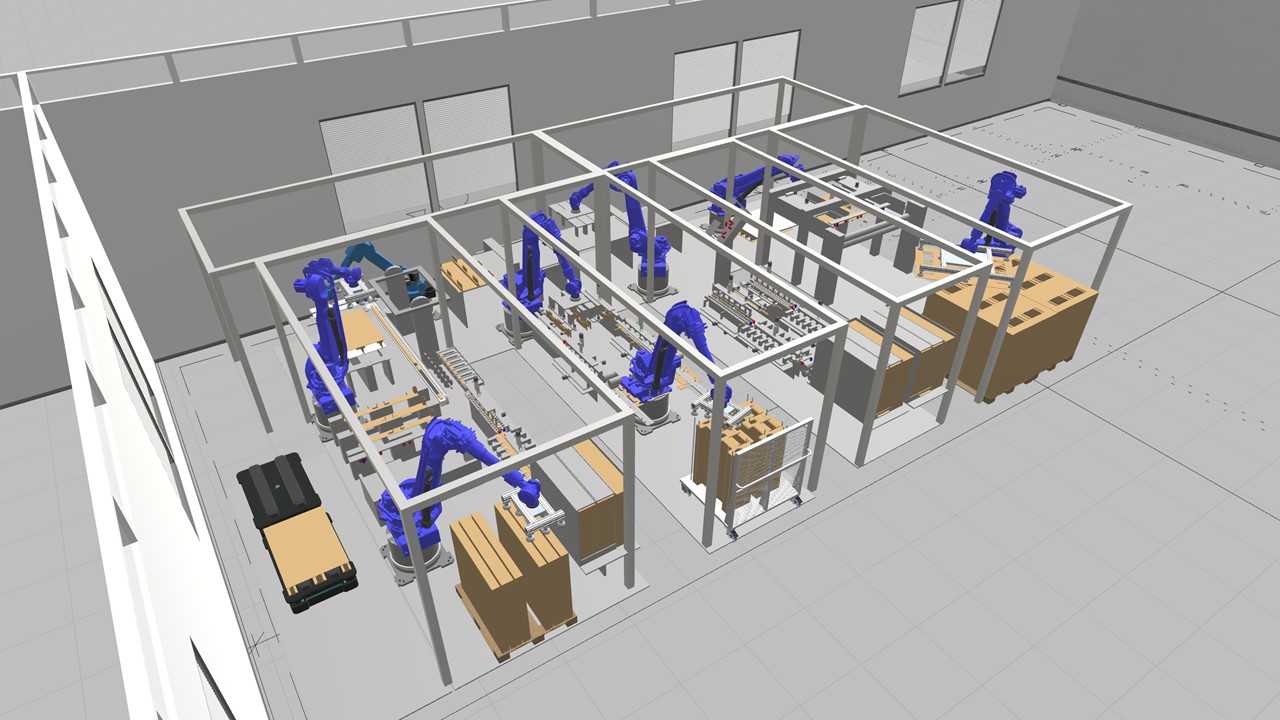

KraftPal Technologies was born to accomplish this. The company has developed proprietary technologies for both corrugated pallet design and the production process. The pallet designs meet international logistics standards in terms of performance specifications (durability and moisture resistance in controlled areas) of wooden pallets. An automated manufacturing process for mass production includes all standard developed pallet designs, including custom designs. The Palletonator (TM) is KraftPal's proprietary robotic machine for mass production of corrugated pallets.

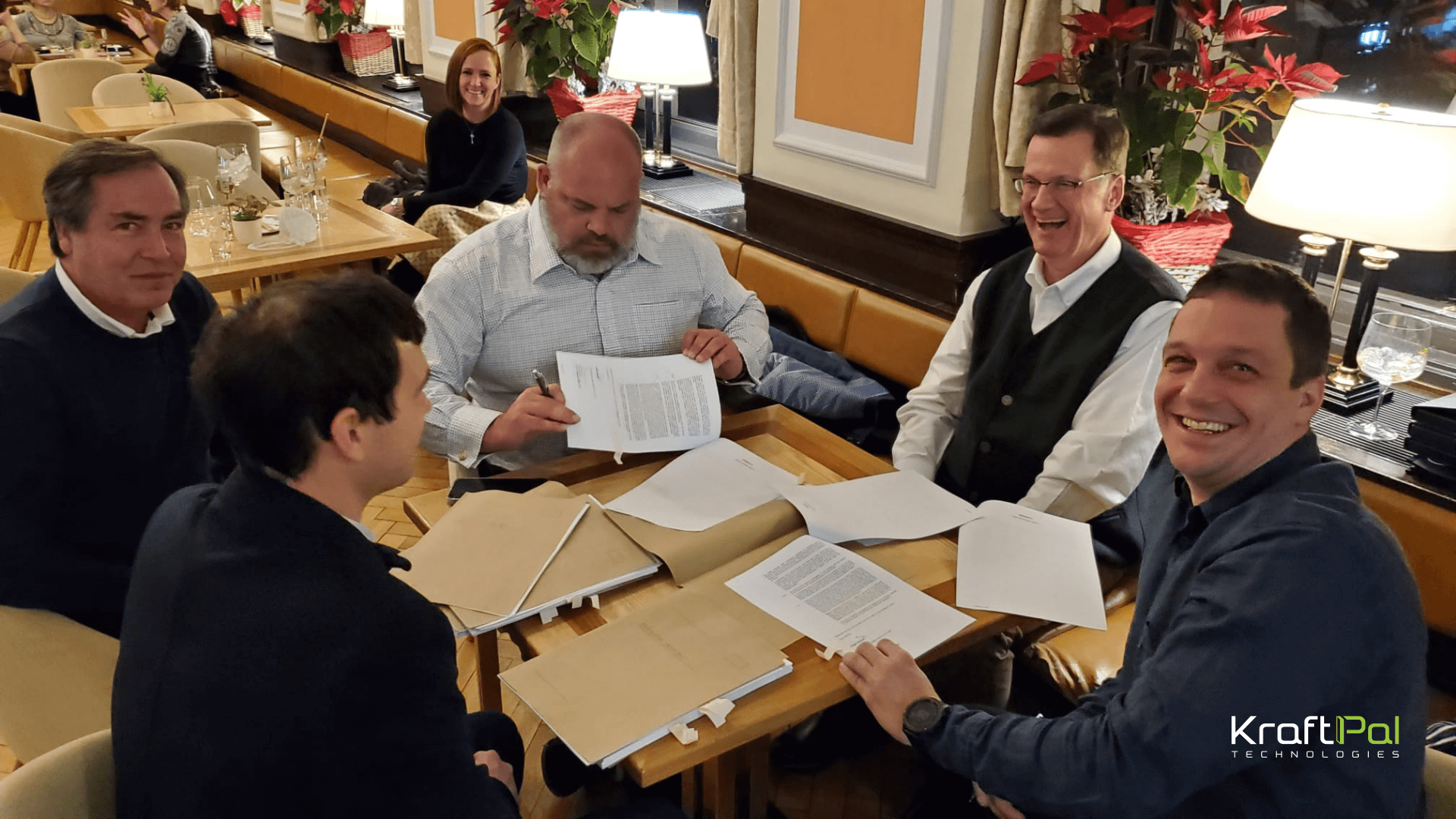

In short, KraftPal is committed to providing environmentally friendly and innovative solutions for cardboard pallets to disrupt the global supply chain. In 2022, the company recruited the best talent from Slovenia, Austria, Finland, Saudi Arabia and the U.S. to join the team, and plans further expansion in 2023.

KraftPal supplies customers on all continents.

The Silicon Review reached out to Gregor Brajovic, CEO of KraftPal Technologies, and here's what he had to say.

"From day one, we have spent most of our time in our R&D center, and just recently we opened two new design centers, one each in Slovenia and California in the United States. The design centers were built to support joint R&D projects with our customers. The main R&D center is equipped with the most advanced technology needed for product development, global paper supplier verification and corrugated board. We also have our own engineering office and production team for mechanical engineering. The Palletonator consists of more than 15,000 components that must meet the highest internal standards. We use FSC certified corrugated cardboard to produce pallets of the highest quality. Constantly looking for better solutions and adapting to new realities is a must in order to stay up to date and maintain our business. A culture of innovation is therefore deeply rooted in the core of our company and represents one of the strongest, if not the strongest, core competencies of our company. Our results have been recognized by the World Packaging Organization, which awarded us the 'Packaging Excellence Award 2021' for our innovation."

Facilitating change

Corrugated pallets, also called paper pallets, are pallets made from sheets of cardboard, corrugated cardboard, and other reinforced paper goods rather than traditional pallet materials such as wood, plastic, or metal. To date, no one has been able to establish the corrugated pallet as a recognized and widely used standard in the global supply chain (along with the wooden pallet). The reason is that all competitors were unable to organize the following three basic elements that are essential to developing a viable, scalable business.

- A product that enables a smooth transition from wood to corrugated board pallets in the supply chain, i.e., a product that performs similarly or the same as a wood pallet, requires no or minimal customization by the pallet user(s), and consumes less raw material than wood pallets.

- Efficient and scalable mass production with the flexibility to produce different standard pallet models that can be adapted to "industry standard" corrugated materials.

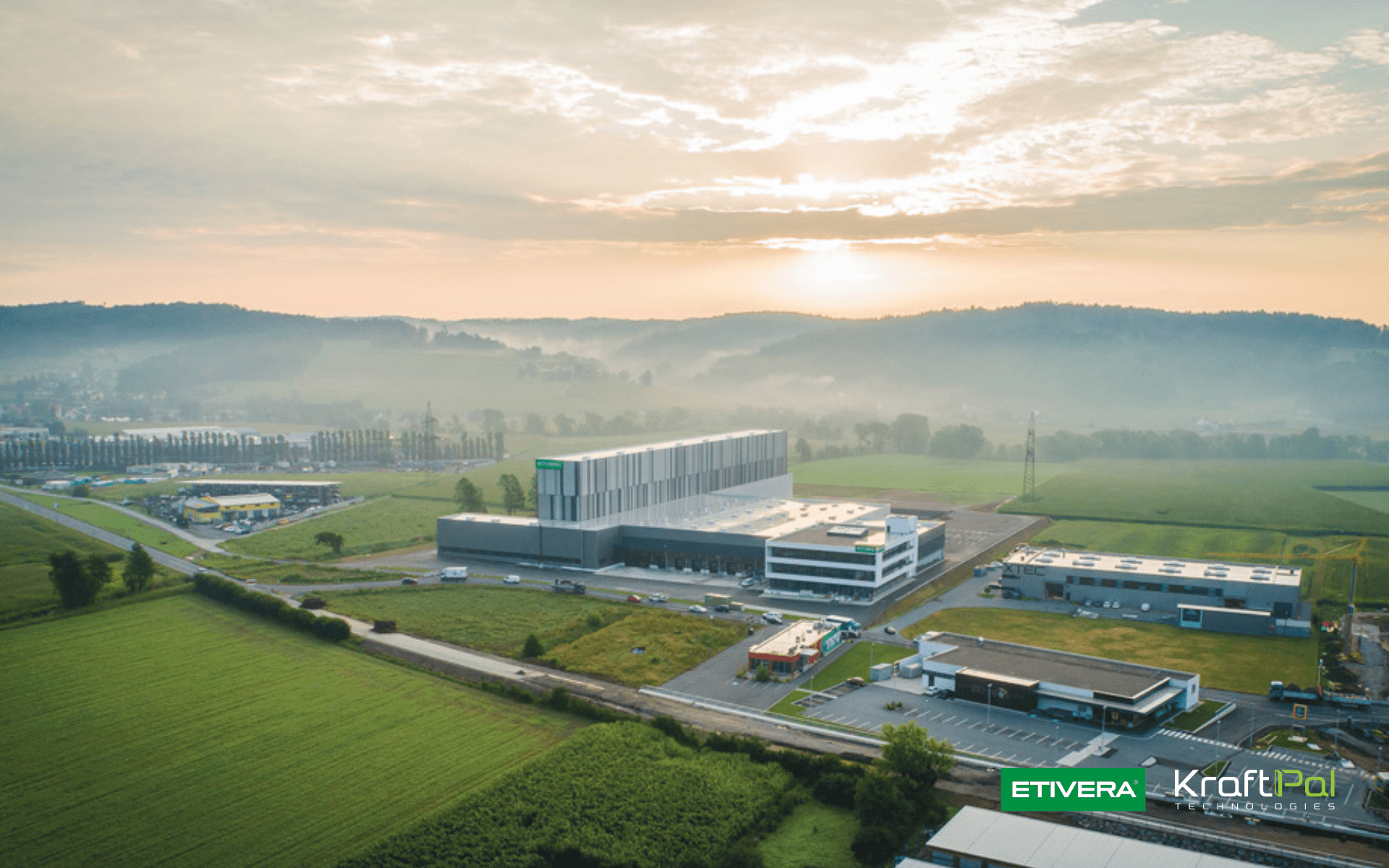

- Sufficient financial and other resources to localize critical business elements to create a global business network of production units close to our customers. The specifics of the corrugated pallet business (high volume, low product prices) make it essential to decentralize the production facilities from which local markets are served.

Aside from these three elements, global trends driven by legislation toward sustainability ensure broad and rapid market acceptance of KraftPal products. All these elements together give KraftPal the unique opportunity to realize its vision and transform the global supply chain with sustainable and future-proof solutions

"At KraftPal, we had to develop product designs and later the production process to enable mass production of these designs. It was also inevitable that the market would dictate development in many directions for so-called standard products, customized products and product integrations - special applications like pallet boxes, etc."

For the first time in the history of the supply chain, pallets made of corrugated board can be used at all stages of logistics: from the first mile to the middle mile to the last mile, that is, from the manufacturer to the customer (not only at the last mile).

"Our goal is to build 60 Palletonators in the next five years and place them at 60 strong industrial sites around the world to produce more than 90 million pallets per year. We will achieve this with core leadership competency and a culture of discipline."

Roadmap

KraftPal plans to build a pilot plant in the U.S. in the second quarter of 2023. The site will be located in the Los Angeles region of California. This will be the first production facility after the Design Center becomes active on U.S. soil. "At the same time, we will already start expanding in Scandinavia and the Western EU."

Gregor Brajovic | CEO

As a professional athlete and a fully qualified lawyer, Gregor, who has worked professionally in Europe, the USA, Africa and Asia, has acquired extensive knowledge of business start-ups in the context of disruptive technology projects as well as in international corporate and tax law. In addition, Gregor Brajovic has extensive experience in compliance, audits, strategic legal due diligence and negotiations in the investment industry. Gregor Brajovic has applied this experience at Kraftpal, made one of the largest investments (in industrial projects) and demonstrated his skills in transforming the pallet market into a modern, sustainable element of the supply chain.

Contact us for more info at sales@kraftpal.com.

The Silicon Review: KraftPal Technologies is transforming the global supply chain with sustainable and future-proof solutions